China PCB Manufacturer and the best PCB Assembly Service

Quick turn PCB fabrication & PCB prototype with one stop service.

8M

PCBs produced annually

3000+

Satisfied Customers

99%

On Time Delivery

98%

PCBs without defects

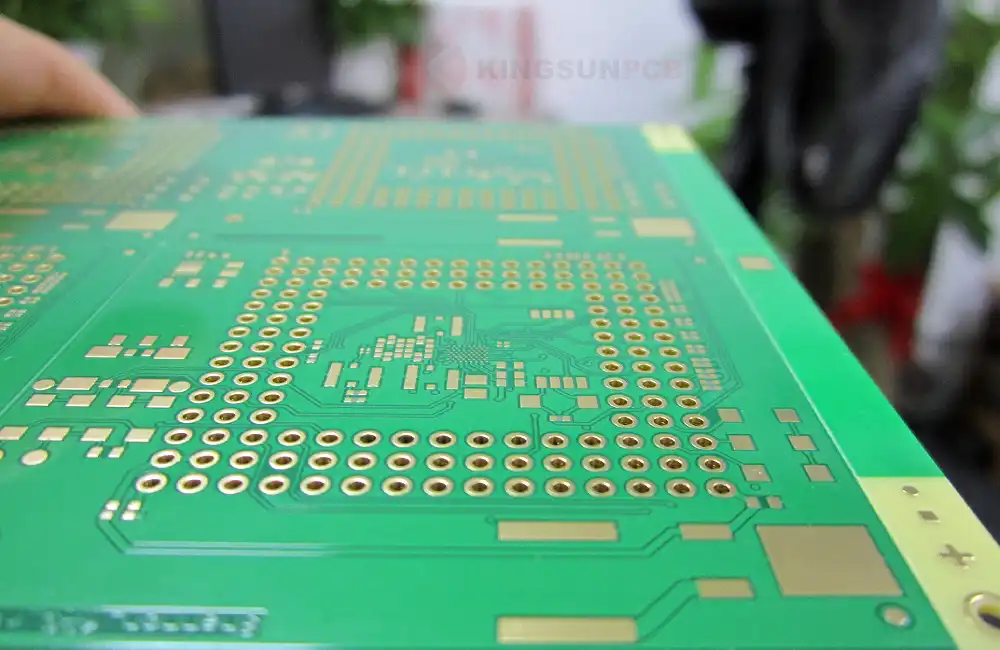

About King Sun PCB

King Sun PCB Technology is a professional PCB manufacturer and PCB assembly supplier in Shenzhen, China.

As a high-end china circuit board manufacturer, King Sun PCB can provide one-stop PCB circuit board manufacturing and PCB assembly services. We can complete all kinds of complex PCB manufacturing.

We have a comprehensive range of PCB products, highly skilled engineers, and rich industry experience. King Sun PCB’s mission is fast delivery and quality assurance. Saving time and costs for customers is our most significant advantage and motivation.

Our PCBs Types

Prototype PCB Board

Quick turn prototype PCB low cost.

- Layers: 1-8

- Quantity: 5-1000 pcs.

- Quality Grade: Standard IPC 2

- Lead time: 2-9 days

- Material: FR4

Standard PCB

Comply with universal design.

- Layers: 1-32

- Quantity: 1-1million pcs.

- Quality Grade: Standard IPC2

- Lead time: 2 days-5 weeks

- Material: FR4

Advanced PCB Design

Used in complex electronic equipment.

- Layers: 1-32

- Quantity: 1-1million pcs.

- Quality Grade: Standard IPC1

- Lead time: 12-15 days

- Type: Flex, Rogers, Alu, etc.

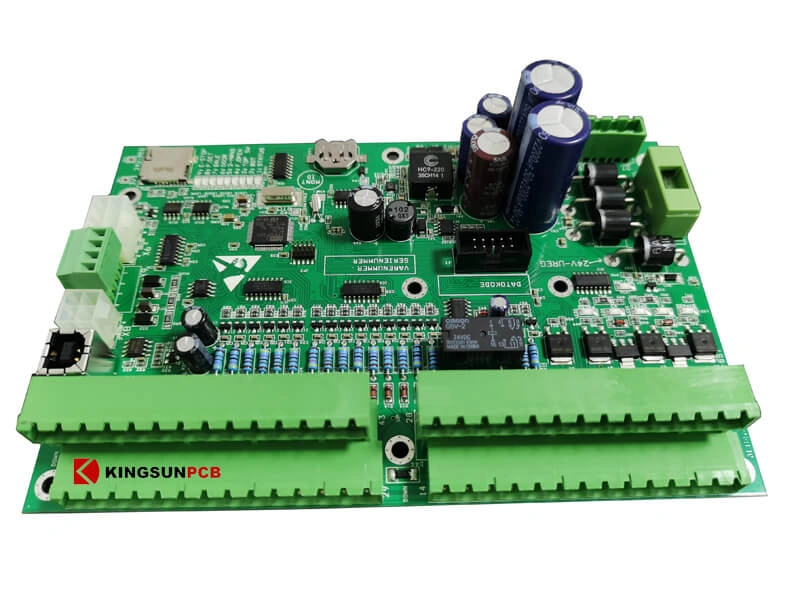

PCB assembly

One-stop PCB assembly services.

- Fulfillment: Turnkey or consigned

- Quantity: 1-10,000+pcs.

- Quality Grade: IPC3

- Lead time: as short as two days

- Other: AOI. X-ray SPI, ICT

Industries We Serve

We develop PCB solutions for every industry, including but not limited to:

Medical industry

Consumer Electronics

LED Lighting

Automobile

Aerospace

Industrial Equipment

New Energy

Marine

PCB Layers We provide

Single-layer PCBs are used in simple electronic products, such as radios, simple speakers, and other OEM PCB products. View detailed types of printed circuit boards.

2 Layer PCB board is widely used in electronic products, from consumer electronics to industrial products, as a cost-effective advantage in China PCB supplier.

A 4-layer PCB contains four conductive copper layers. The top and bottom layers are the signal layers, and the middle two are the power and ground layers. The power and ground layers can be isolated in the middle to reduce interference.

MultiLayer PCB emerged with the development of science and technology, and electronic products are required to be portable and smaller.

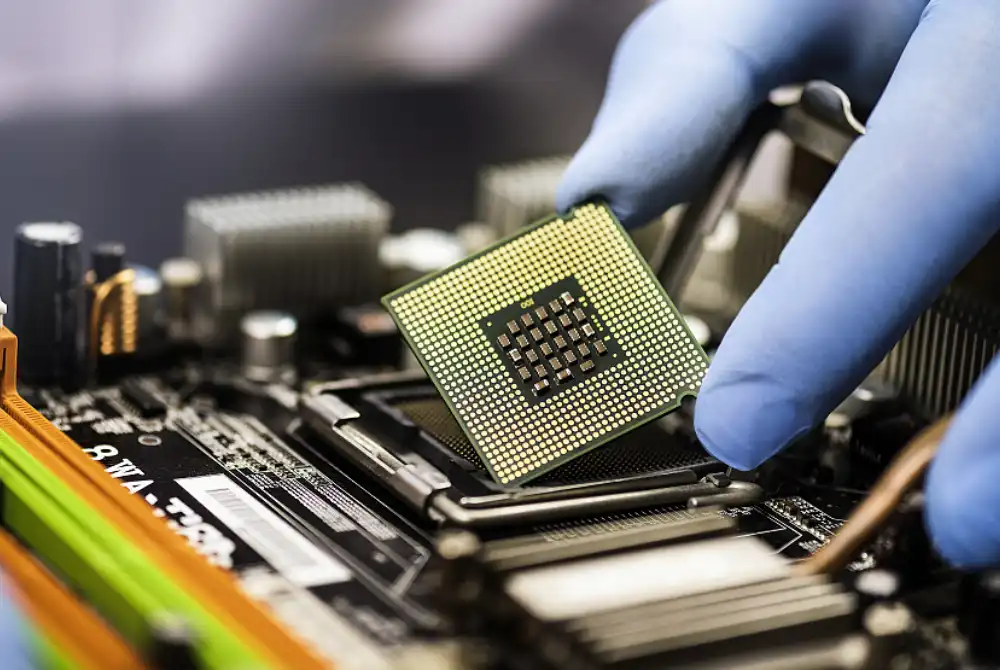

PCB Assembly

PCB Components Purchase

We have a complete material procurement management and control process and can quickly provide customer component quotations. We also accept customers who provide BOM materials to our PCB assembly factory.

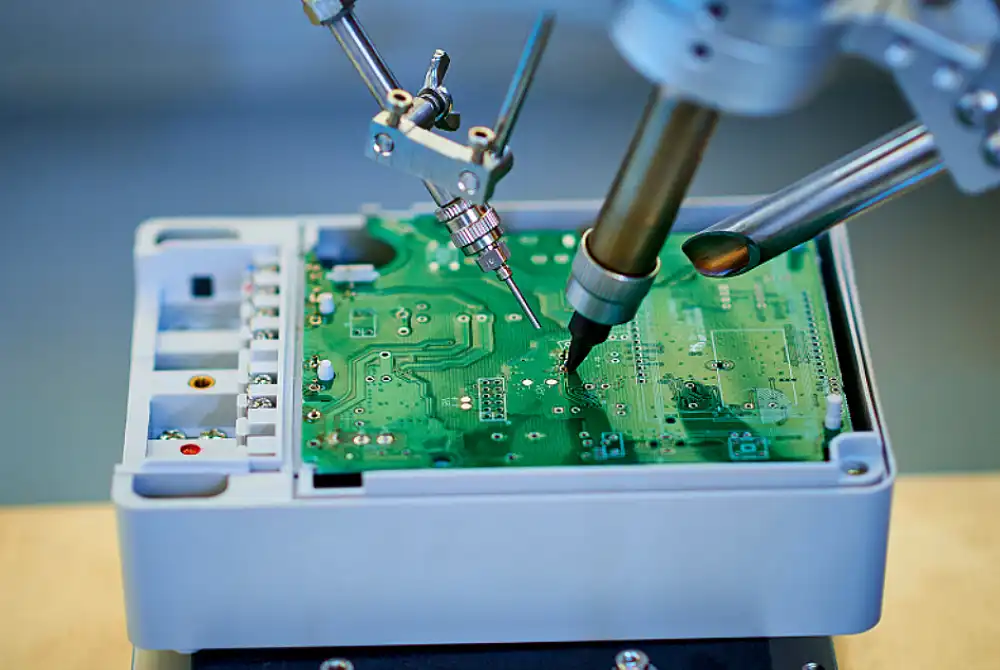

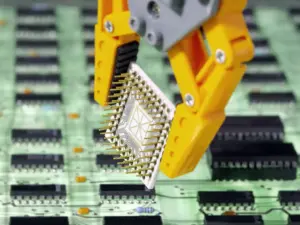

SMT Assembly Processing

Our PCB assembly manufacturer has first-class equipment, a perfect quality control system, and rich practical experience, which makes our PCB assembly highly efficient, high quality, and price-advantaged.

Through Hole Assembly

After the PCB assembly is finished, SMT enters the through-hole assembly. Through-hole assembly generally adopts the wave soldering process, and the wave soldering machine is used for welding processing and firm components.

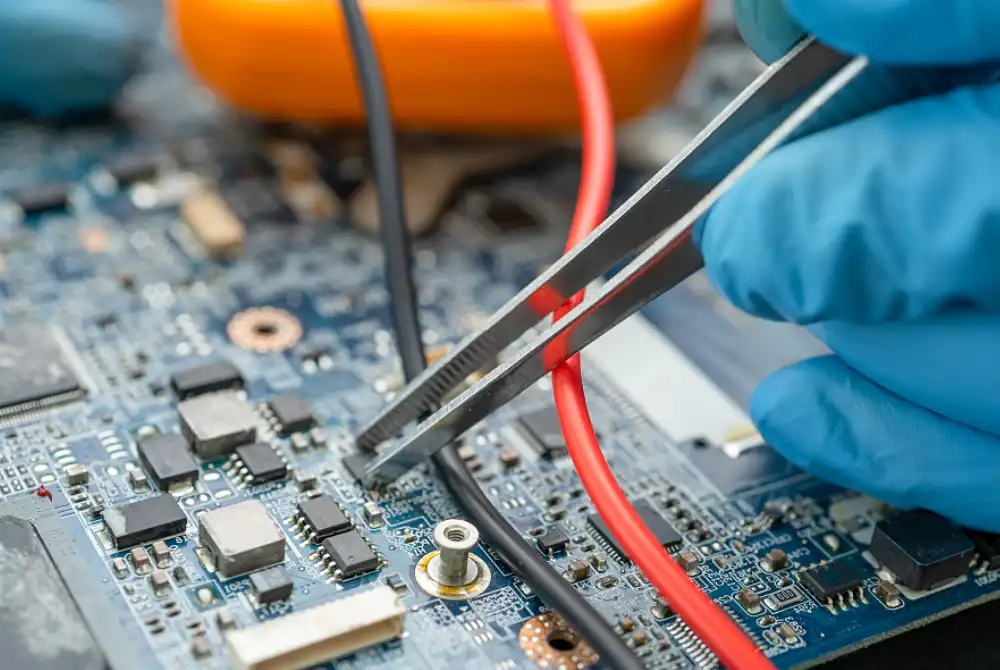

PCB Assembly Testing

We will do a PCB functional test for PCB assembly according to the customer’s requirements.